|

Introduction to industrial painting division |

|

Industrial coating division was established in 2007, specializing in industrial coating industry marketing, sales, technology, construction and acceptance, training and after-sale systematic study, after ten years struggle now and trinity, the wind, fiat, kia, geely, dongfeng, suzuki, sichuan steam, tahe jinan motorcycle, baling technology, jiaxing keen sensitivity, etc. Division is very pay attention to the cultivation of professional talents, sales jobs or technical positions require from two aspects of practical application and the national standard for a long time in-depth study, because industrial coating fire itself belongs to party a and b at high risk of fire, in terms of design, construction, user has its special requirements and matters needing attention, so keep learning new technology, constantly absorbing all kinds of lessons become industrial painting tradition all the members of the group. Division since 2007, the successful completion of sany heavy industry (lingang) in mianyang, sichuan auto industry group automobile manufacture co., LTD., shandong wind (group) co., LTD. (new energy), Vietnam changhai kia motors co., LTD., first and second period, hunan changsha fiat auto co., LTD., wuhan sanhuan, zhongheng day automotive group (ya) geely automobile co., LTD., ningbo DMA project, nanjing iveco automobile co., LTD. (ning pukou bridge), guangxi country shuanglin auto parts co., LTD. (liuzhou), tahe jinan motorcycle suzuki motorcycle co., LTD., their honor suzhou computer (suzhou) co., LTD, suzhou source into aluminum manufacturing co., LTD., jiangyin association's car, jiaxing keen sensitivity of real vehicle or component coating items.

Taicang suan fire equipment co., LTD. Address: no.18, no.18, gate south road, liuhe town, taicang city postcode:215431 tel:0512-81605191、81605190

Mr Chen:13814885163 Mr Zou:13962627004 Mail box:suanfire@126.com

|

|

Discussion and countermeasures on fire fighting in painting workshop (zou ling) |

● preface

In recent years, with the completion of several large car production lines, the coating process and equipment that represent the most advanced level in the world have already appeared in China. But throughout the domestic existing design construction and the introduction of the number of 10 coating line, to closely related to process equipment workshop fire rating classification and workshop in fire control system configuration, the lack of fire control countermeasure selection principle of unified basis. To make the coating workshop to be both safe and reliable, meet the fire code requirements, and save investment, economy applicable, must be the coating workshop production process characteristics and to study the fire risk analysis, on the premise of meet the existing specifications, put forward the corresponding reasonable fire control measures, and citing relevant regulations and examples at home and abroad, puts forward some views.

● Classification of fire hazard in painting workshop

The coating production process is more complicated, the fire risk of different processes is very different. The spray paint room and paint are used for the use of or storage of a or b combustible materials such as organic solvents, which are usually classified as a and b. And the pretreatment, electrophoresis, putty and other processes that make up the proportion of the workshop area, are operated in a waterborne environment, and are basically free of fire risk. Based on the above mentioned above, in the design of the coating workshop factory, the fire risk (or production category) of the whole workshop is classified as a and b, and it is also classified as d and e. Different production categories, its fire protection system selection and facility size, configuration requirements are very different, at the same time fire resistance level, structural fire prevention measures. The partition of fire zone and the selection of process materials will have a serious impact. Such as the workshop of the whole fire risk as a, b, according to the code for fire protection design of buildings (GBJ16-87, hereinafter referred to as the "build rules") requirements, building fire resistance rating must be a, level 2, and is widely used in paint shop light steel structure workshop is not meet the requirements. Therefore, the reasonable determination of the overall production category of the coating workshop is the main problem that relates to the economy, application and production safety of the workshop.

Current coating operation safety procedures in our country, painting process safety "(GB6514-95), including all kinds of organic solvent coating can be divided into class a, powder coating for b, water-based paint, latex paint for the c class.

The above classification is only for the fire risk determination of different coatings, and cannot represent and define the production category of the whole painting workshop. The determination of the current workshop production categories in China is based on the provisions of the provisions of the code of fire prevention of architectural design (gbj16-87, hereinafter referred to as the "construction rules").

In the (construction rules), according to the production nature, production materials, operating conditions, products and other factors. The fire risk of existing production plant is divided into five categories according to the order of a, b, c, d and e, among which, the fire risk of class a is the highest, the lowest of the e.

Said the "build rules" article 3.1.1 to paint (coating) workshop, "when closed spray-paint technology is used, closed between maintaining negative pressure, spray paint room and paint room set concentration of combustible gas alarm system or automatic explosion suppression system, paint section where the fire partition area percentage is less than 20%, the workshop is decided by butyl e class".

The new coating workshop, the use of special paint spraying equipment, such as water, water cycle and spray paint room, are steel sealing equipment, exhaust system is complete, indoor can maintain negative pressure by adjusting, etc are set up according to the requirements of explosion-proof electrical equipment and lamps and lanterns, and are equipped with the concentration of combustible gas alarm system. At the same time, the total area of the workshop, including spray paint, flow (air drying), drying equipment and paint mixing storage room, shall not exceed 20% of the total workshop area. All the above conditions have met the requirements of the 3.1. L bar of the building rules, so the fire hazard in the coating workshop is determined by the determination of the butyl class.

"Build rules. 3.1 l article also pointed out:" in the workshop or in the laboratory, a small amount of use of inflammable and explosive dangerous goods (class ab), want to consider all of its volatile after diffuse throughout the workshop or in the laboratory, with air mixing ratio is less than 5% of the lower explosive limit as defined by the class ab fire risk incurred is not ". But the CO2 automatic fire extinguishing system design specification (GB50193-93) 3. 2. L. l a fixed total flooding CO2 fire extinguishing system provided in reserve should be basic closed space, in front of the discharge of CO2, the side walls can't close the open area of less than 3% of the surface of protection zone, and should not be at the bottom of the openings. There are artifacts of the import and export on both ends of the spray room, due to the need of production and the limitation of transportation mode, generally can't be closed, although the area is less than 3% of the total surface area, but there is a fire when it is difficult to control the opening of CO2 loss, so it is difficult to ensure that the CO2 fire extinguishing concentration. Structure from the device itself is concerned, regardless of the water, water spray paint room or venturi spray paint room, due to its forced exhaust and the characteristics of water supply for the open cycle, at the bottom of the device are relatively large openings, unable to form CO2 fire extinguishing system to put out the fire when the required basic closed space, it is actually conflict with CO2 fire extinguishing system design specification requirements. Therefore, the CO2 extinguishing system is not very suitable for the spray paint room fire. If the CO2 automatic fire extinguishing system is to be installed in the spray paint, the necessary measures should be taken. The bottom of the device can be closed at the time of the fire and the CO2.

● economy

CO2 automatic fire extinguishing system device, because of its special performance and high pressure, complex control requirements, everything from the materials, processing technology to the installation and debugging must comply with the strict technical standards, and therefore cost was significantly higher than that of general fire extinguishing system. The total cost of a set of CO2 fire extinguishing system (including installation and commissioning and personnel training) of the motorcycle coating line is about 40 ~ 500,000 yuan. Car coating line a CO2 fire extinguishing system total cost is about 80 ~ 1 million yuan, all is the same size of about 5 times the price of the automatic sprinkler system, this is a big burden for domestic enterprises.

● reliability

The refilling and daily maintenance of CO2 extinguishing system are higher than other fire-fighting systems. Domestic has repeatedly occurred due to management and operation, resulting in CO2 fire extinguishing system in the absence of any fire occurs misoperation, in CO2 gas injection system, and replacement parts to filling CO2 economic loss of 100000 yuan. Therefore, coating workshop should be equipped with a special fire safety management personnel, strict professional training, to ensure the normal work of the CO2 fire extinguishing system, and in the case of false alarm, timely find and stop the false operation of the system.

To sum up, the use of CO2 extinguishing system in the fire-fighting equipment in the spray painting room is not the ideal choice in terms of necessity, practicality and economy. Suggestions on the spray room fire control system configuration, according to the nature of the spray room fire and investment, resources condition and the opinions of the local fire department, in CO2 automatic fire extinguishing system, sprinkler system, water spray system, portable fire extinguisher discretion to choose in the system. Some small, low-load spray paint rooms, portable fire extinguishers.

● Automatic spraying equipment fire fighting

As the production of surface coating quality requirements and production increased significantly, the use of automatic spray technology is becoming more common, newly built large coating line in painting indoor set up automatic spraying equipment. This kind of equipment automation is high, control complex, most rely on import, cost is expensive. Therefore, fire protection of automatic spraying equipment should not be ignored.

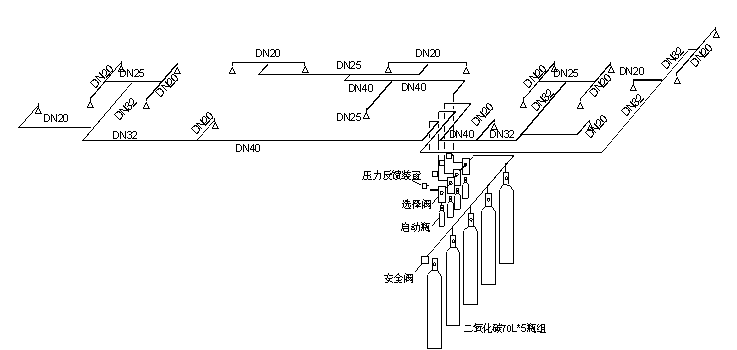

At present, for automatic spraying equipment fire protection in the world is on the spraying equipment accessory local application system, formulate a set of independent CO2 to import in automatic spray gun (cup), there is a fire, according to the alarm signal automatically switch, automatic spray gun (cup) emitting CO2 gas, will automatic spraying equipment, isolation from the air, in order to protect the automatic spraying equipment. Supply the set of CO2 system is only connected with automatic spraying equipment, is not between the paint and the overall fire control facilities in transverse connection, independence is strong, and does not affect the choice of the spray room fire system type.

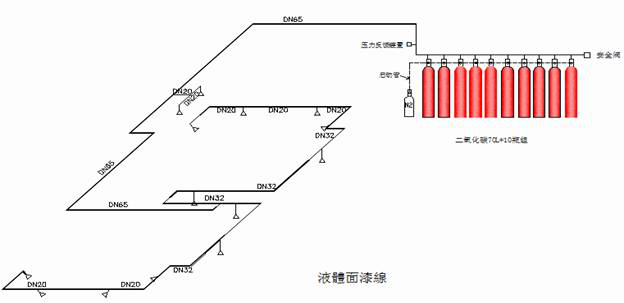

● Paint storage and fire fighting between paint

Between the paint storage room and the paint room, usually only 1 ~ 2d paint and solvent. Due to more combustible materials, poor ventilation or poor management, the large amount of solvent and vapors can cause explosion fire because of static electricity or other sparks. Therefore, the coating workshop fire - proof focuses on the paint storage room and the paint room.

In addition to setting fire hydrants and fire extinguishers in accordance with the general requirements of the building regulations, automatic alarm system and automatic fire extinguishing equipment must be set up. Considering the cost reasons, automatic sprinkler system can also be used.

|

The fire planning procedure of the painting section |

A number of problems and solutions for the design and use of fire detectors in the painting section.

Fire hazards and solutions of the exhaust ventilation system of the painting section.

There is a spray coating process